Pressure: 4.8MPa or higher

-

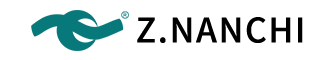

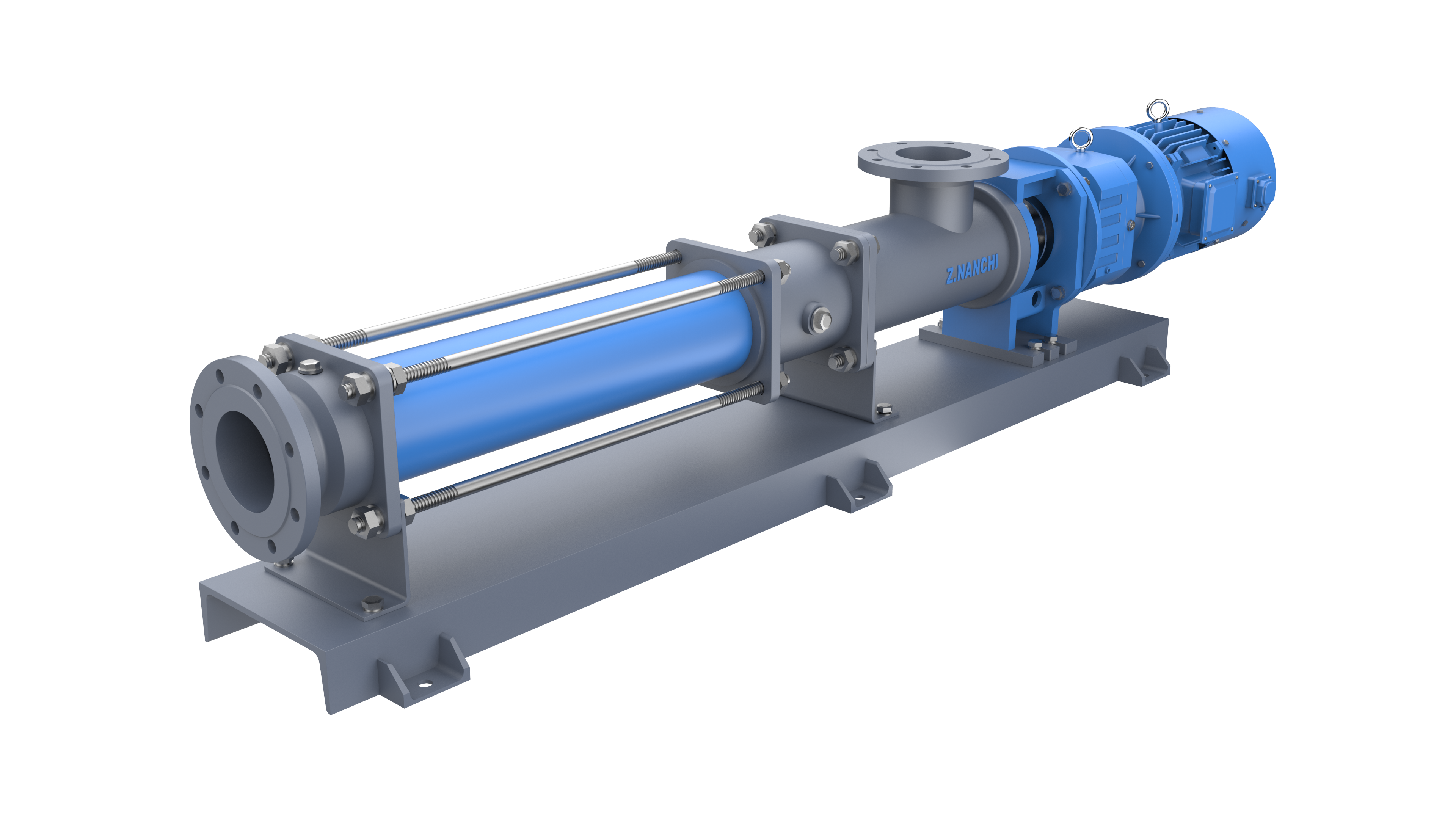

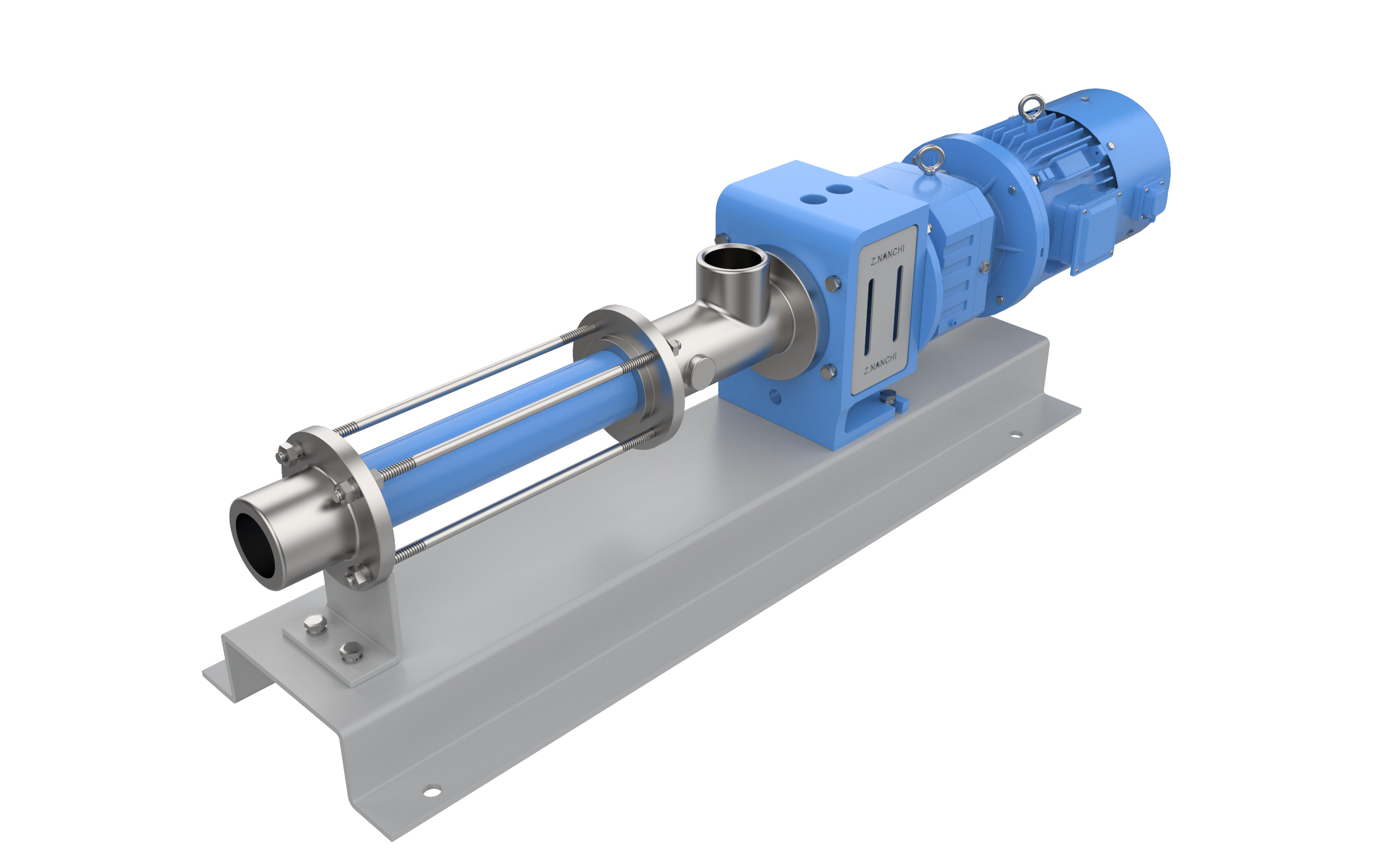

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

Pressure: 4.8MPa or higher

-

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

Pressure: 4.8MPa or higher

-

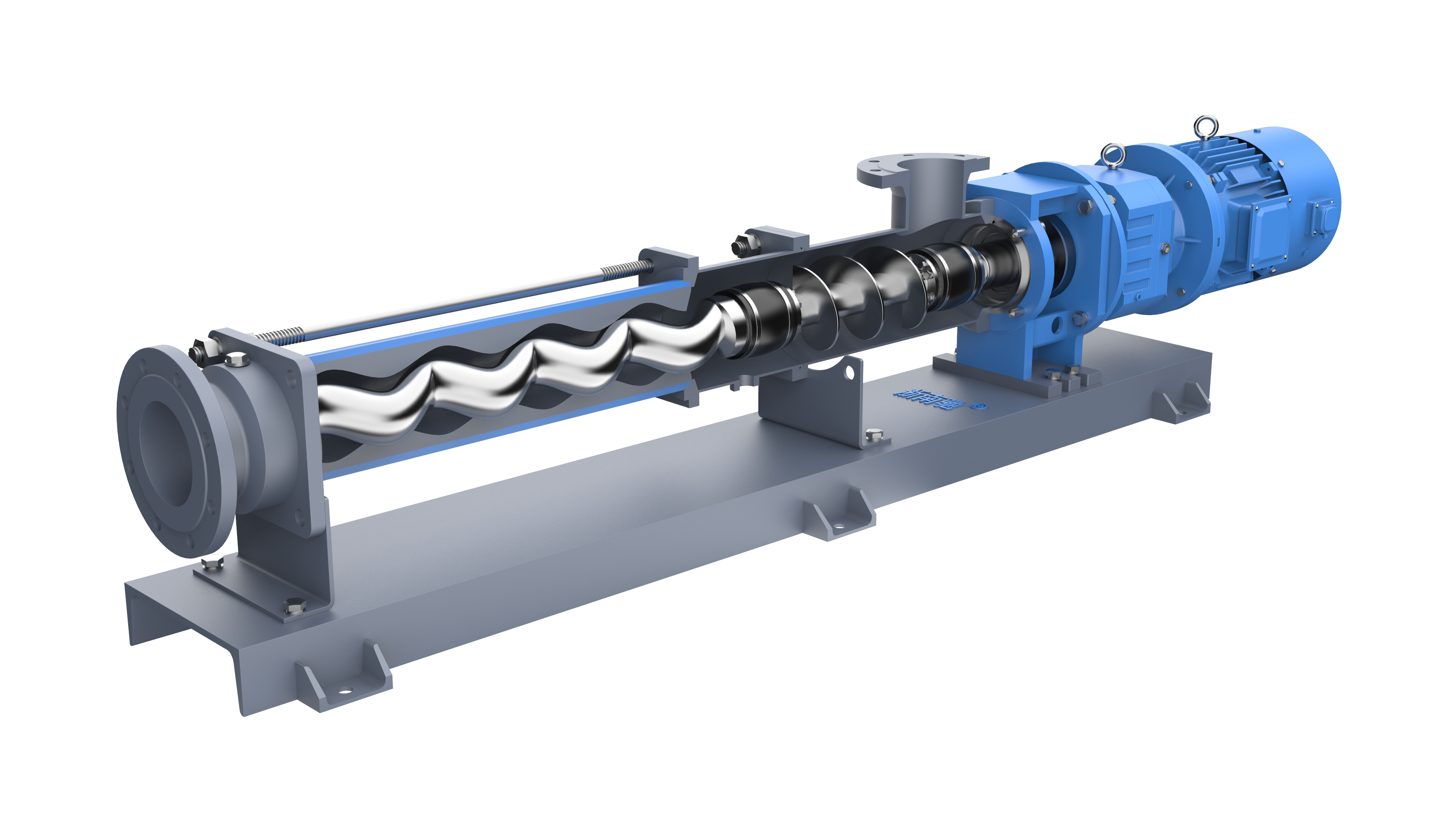

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

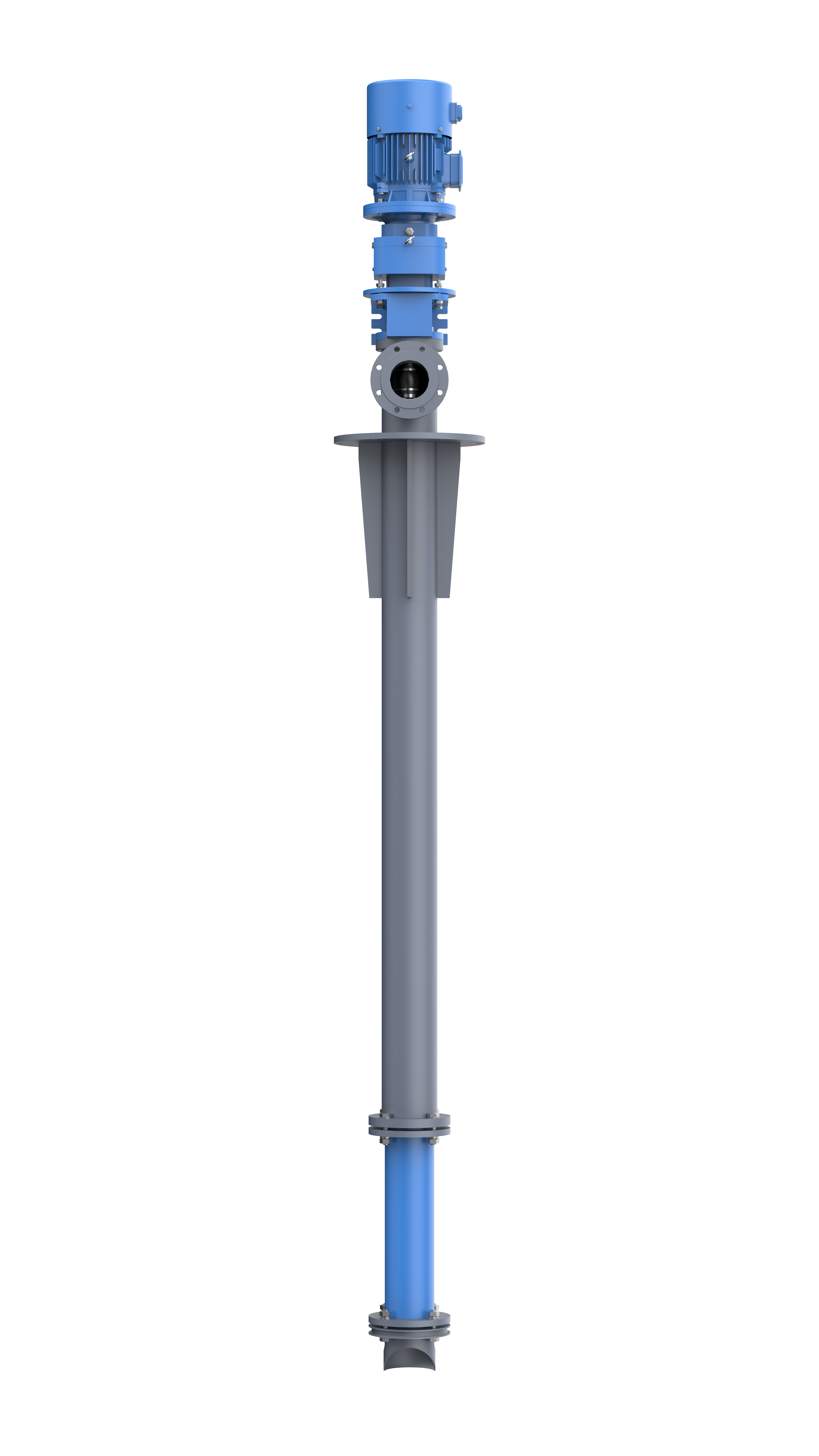

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

Pressure: 1.2MPa or higher

The sludge is reduced through dehydration treatment. After adding flocculants and mechanical dehydration through belt filter presses, centrifuges, plate and frame filter presses, or other dehydration equipment, the free water in the sludge is removed and turned into dehydrated sludge with a solid content of 18-45%.

Due to significant changes in the physical properties of sludge, the selection of equipment in the sludge dewatering system must be flexible in handling these situations.

Solution

Among the numerous applications in the environmental protection industry, Z.NANCHI pump's agile conveying technology has performed well and won widespread recognition. Ensure that the entire pump is always in optimal operation, significantly reducing the life cycle usage cost of the entire pump, and improving operational performance.

Some application cases include:

- NT series pumps of different models, vertical screw pump is used for feeding of dehydration system.

- NT series pumps of different models are used for conveying dehydrated sludge.

- NQ series crushing and cutting machine is used to treat rags in materials, homogenize sludge, and reduce the particle size of solid components in materials by vertical screw pump.

- The peripheral injection system reduces pipeline friction loss and improves system operation efficiency.

- The NKZ series control system can not only improve the feed efficiency of the dehydration equipment, but also assist in the subsequent treatment of dehydrated sludge.

- Professional transportation of dehydrated sludge, including long-distance transportation solutions.

- Tailored solutions based on different processes.

- Design the most economical professional dewatering sludge whole pumping solution.

Z.NANCHI pump series products are widely used in the treatment of industrial wastewater, urban sewage, and sludge. The continuously developed new processes and technologies not only reduce the amount of sludge treatment, but also enhance the effectiveness of sludge treatment, achieving resource recovery and utilization to generate renewable energy. These are constantly changing the industrial form of this industry. In summary, finding the optimal, most economical, and most advanced solution is crucial.

Solution

The Nanchi pump transportation technology has performed well in numerous applications in the environmental protection industry. Maintain the optimal operation state of the whole pump, significantly reduce the life cycle use cost of the single Screw pump, and improve the operation performance.

Some application cases are as follows:

- The primary sludge and secondary sludge are transported to the concentration unit and dehydration equipment through the NG type pumps and other screw pumps.

- The concentrated sludge is transported to the digestion tank through NG and NT pumps.

- Dehydrated sludge is mixed back into concentrated sludge through NT series pumps for subsequent treatment.

- NT series pumps are equipped with corresponding control systems to treat dehydrated sludge.

- The NQ series crushing and cutting machines are used to handle common solid and fibrous substances in the industry's materials.

In each step of processing, the decisive advantage provided by Z.NANCHI is:

- short pump design

- low maintenance requirements

-

low operating costs

-

comprehensive service

Through Z.NANCHI technology, the sludge is efficiently transported to the thickener and dehydrator, and further conditioned. Z.NANCHI single screw pump manufacturer can cooperate with subsequent disposal processes such as drying, incineration, thermal hydrolysis or biological energy generation.

The sludge has reduced its moisture content and achieved volume reduction through thermal drying. Dried sludge can be compressed into particles for incineration or used for fertilizer production.

Sludge drying and incineration treatment centers usually also process sludge from external sources. Different sources of sludge may include primary sludge, activated sludge, excess sludge, or digested sludge. As a result, the entire pump delivery system faces various complex and demanding requirements.

Solution

Combined with different application processes of dewatered sludge, Z.NANCHI, as a manufacturer of high-quality single screw pump, provides a perfect whole sludge pump transportation system.

- Dewatered sludge or foreign sludge is transported into temporary storage bin through NT type pump and single screw pump.

- NT type pump, a single screw pump, conveys dewatered sludge in the temporary storage bin to the drying equipment or the prefabricated bin of the incinerator.

The significant advantages of Z.NANCHI's entire pump delivery system:

- Continuously feeding the incinerator or drying equipment with the smallest pulse.

- The feeding hopper can be flexibly adapted according to the silo or discharge hopper.

- The NT pump with material storage function can save additional storage facilities and space in the factory.

Z.NANCHI is a professional single screw pump and screw pump manufacturer, which provides the sludge treatment centers with solutions for whole pump transportation and overall control to meet various requirements.

The dehydrated sludge treated by sludge treatment centers often comes from both local and foreign sources. There are sludge storage silos both underground and on the ground. If necessary, sludge backmixing must be carried out to the correct feeding for subsequent treatment.

Solution

Some application examples are as follows:

- Sludge with solid content of 18-35% is transported to temporary storage point through NT type pump, single screw pump and vertical screw pump.

- The dehydrated sludge is mixed back into the concentrated sludge through an NT type pump, and then conditioned to the required solid content in the subsequent treatment process.

- The flowing sludge is sent to the Z.NANCHI mixed transport pump through the Z.NANCHI NT pump.

- The peripheral injection system, feed hopper liquid level monitoring, pressure monitoring, and/or dry running protection devices are comprehensively controlled through the NKZ control system.

In terms of the application of sludge mixing, the special advantages of the Z.NANCHI conveying solution are:

- High solid content sludge conveying capacity.

- Even for long-distance transportation, the transmission volume remains constant.

- Treatment capacity of high viscosity sludge.

- Advanced spiral feeding technology.

- Tailored feed hopper and whole pump for different applications.

The most suitable solution for sludge mixing comes from Z.NANCHI.