Pressure: 4.8MPa or higher

-

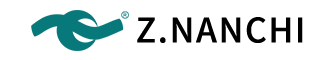

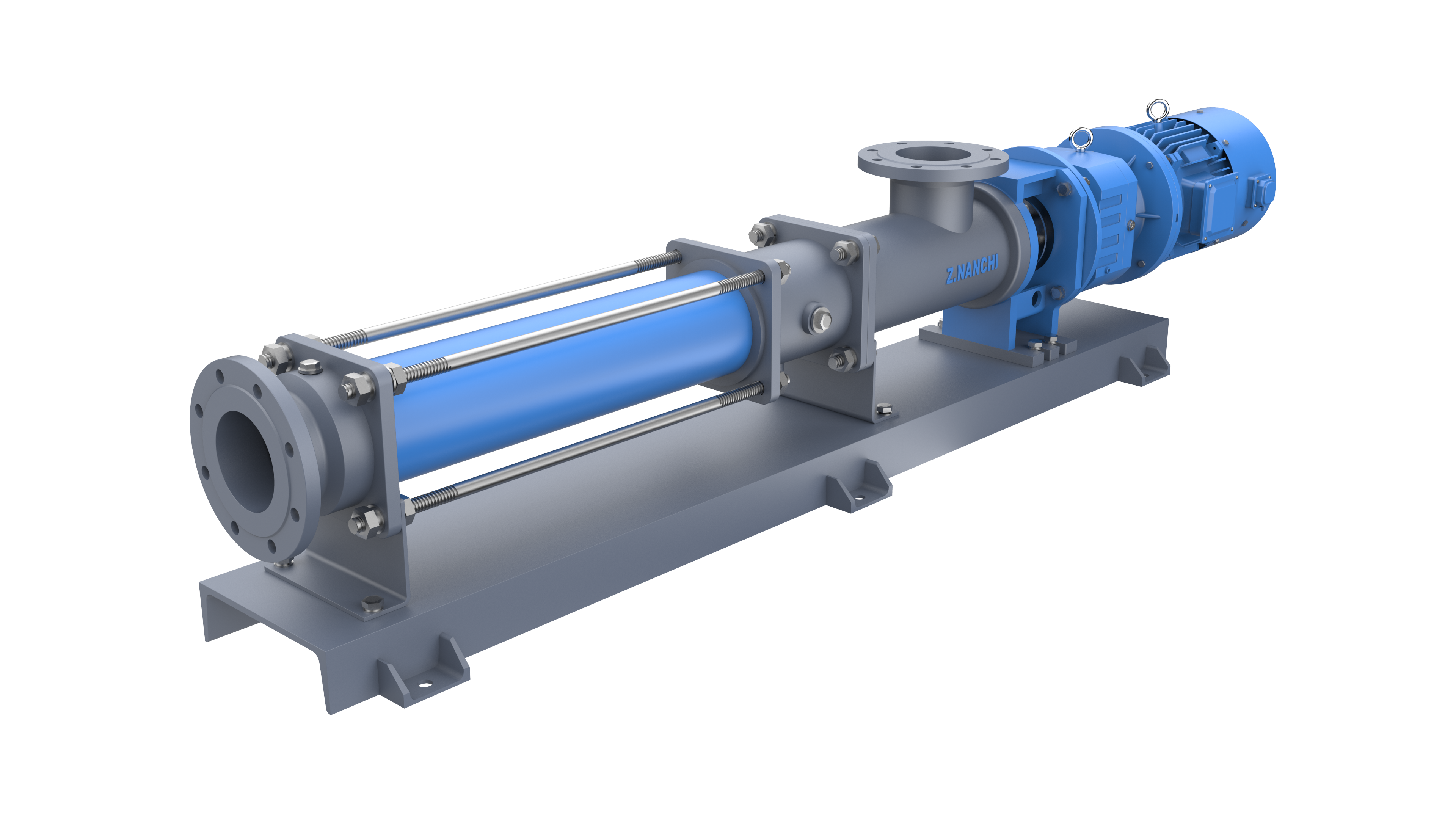

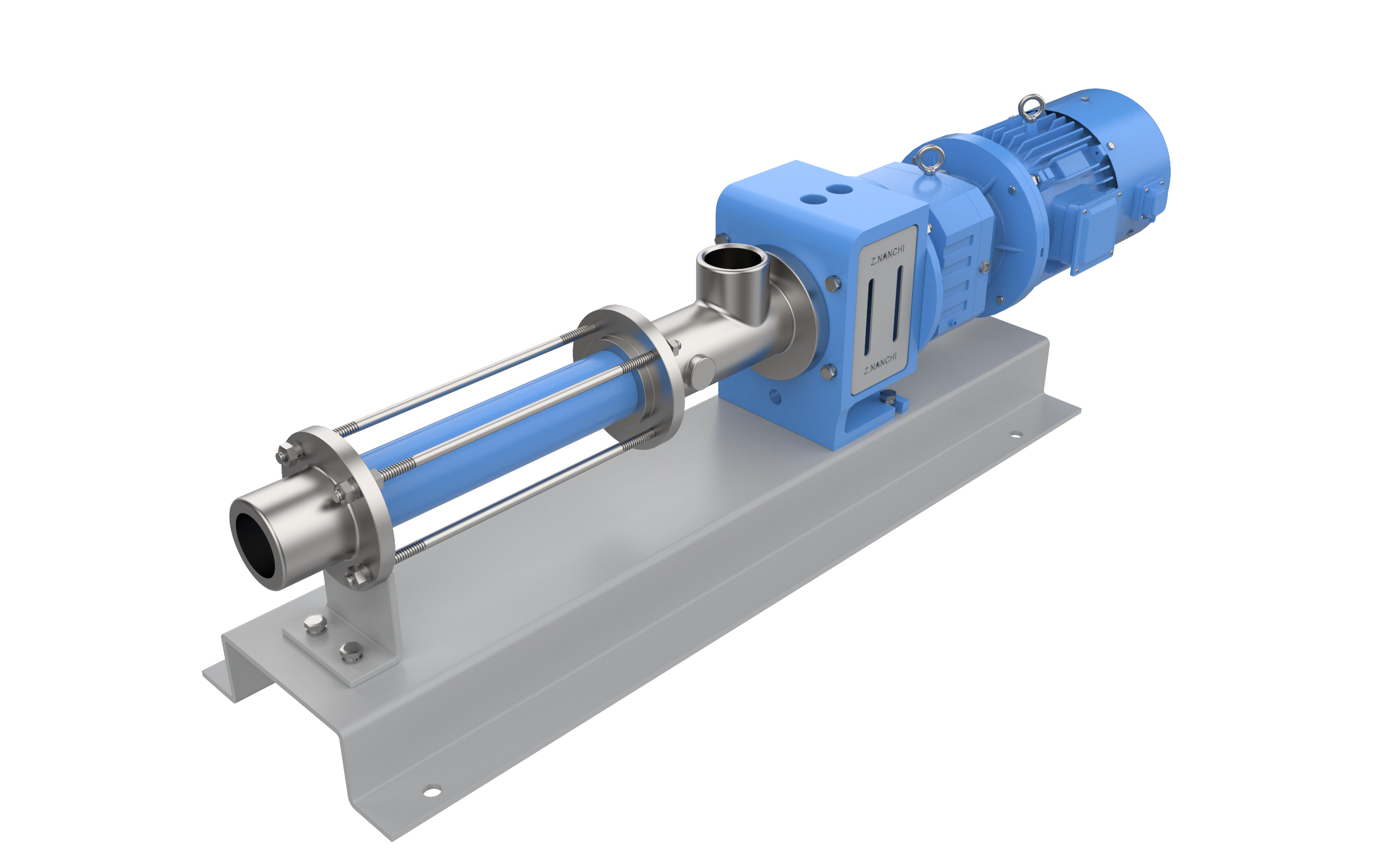

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

Pressure: 4.8MPa or higher

-

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

Pressure: 4.8MPa or higher

-

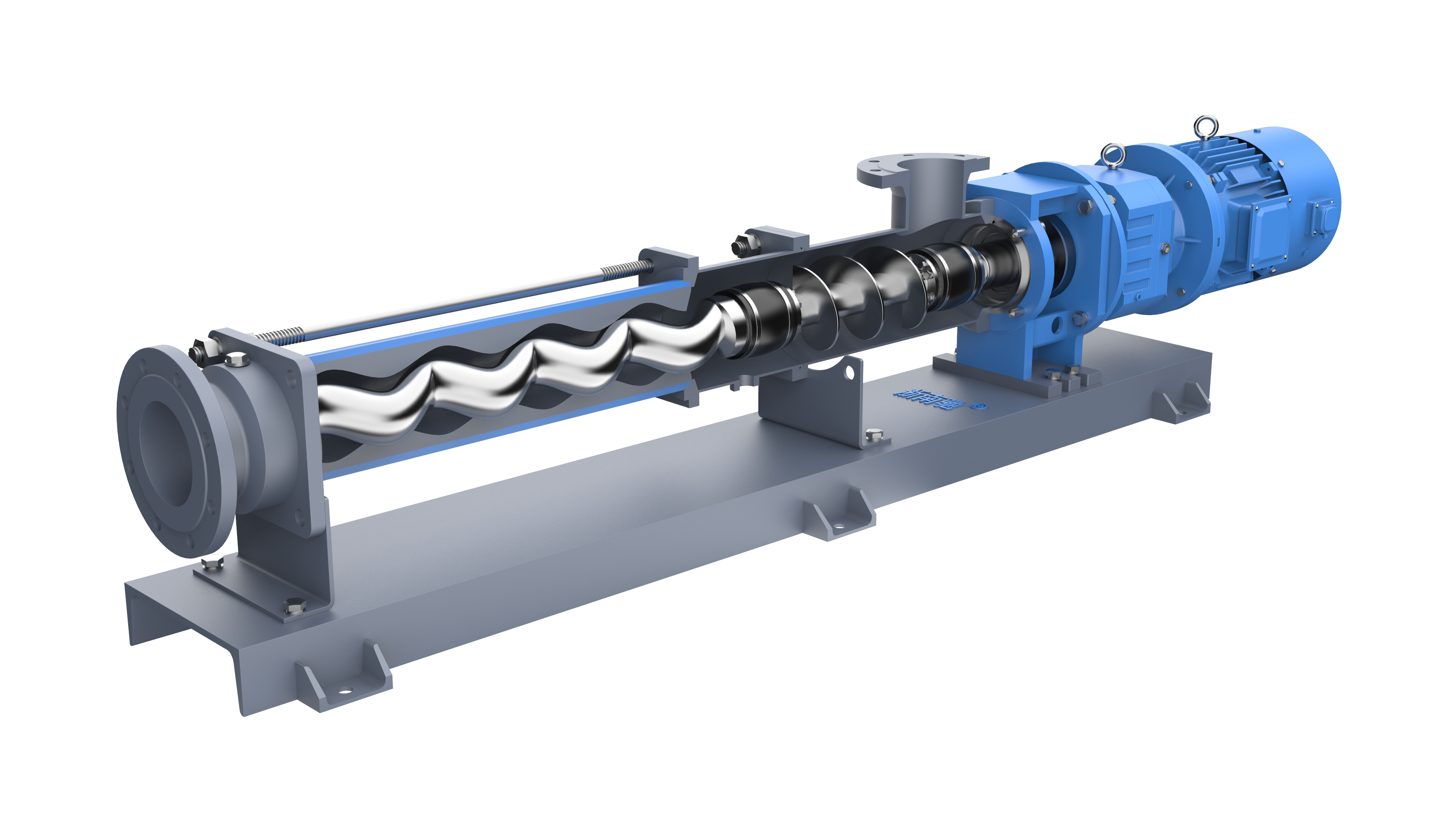

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

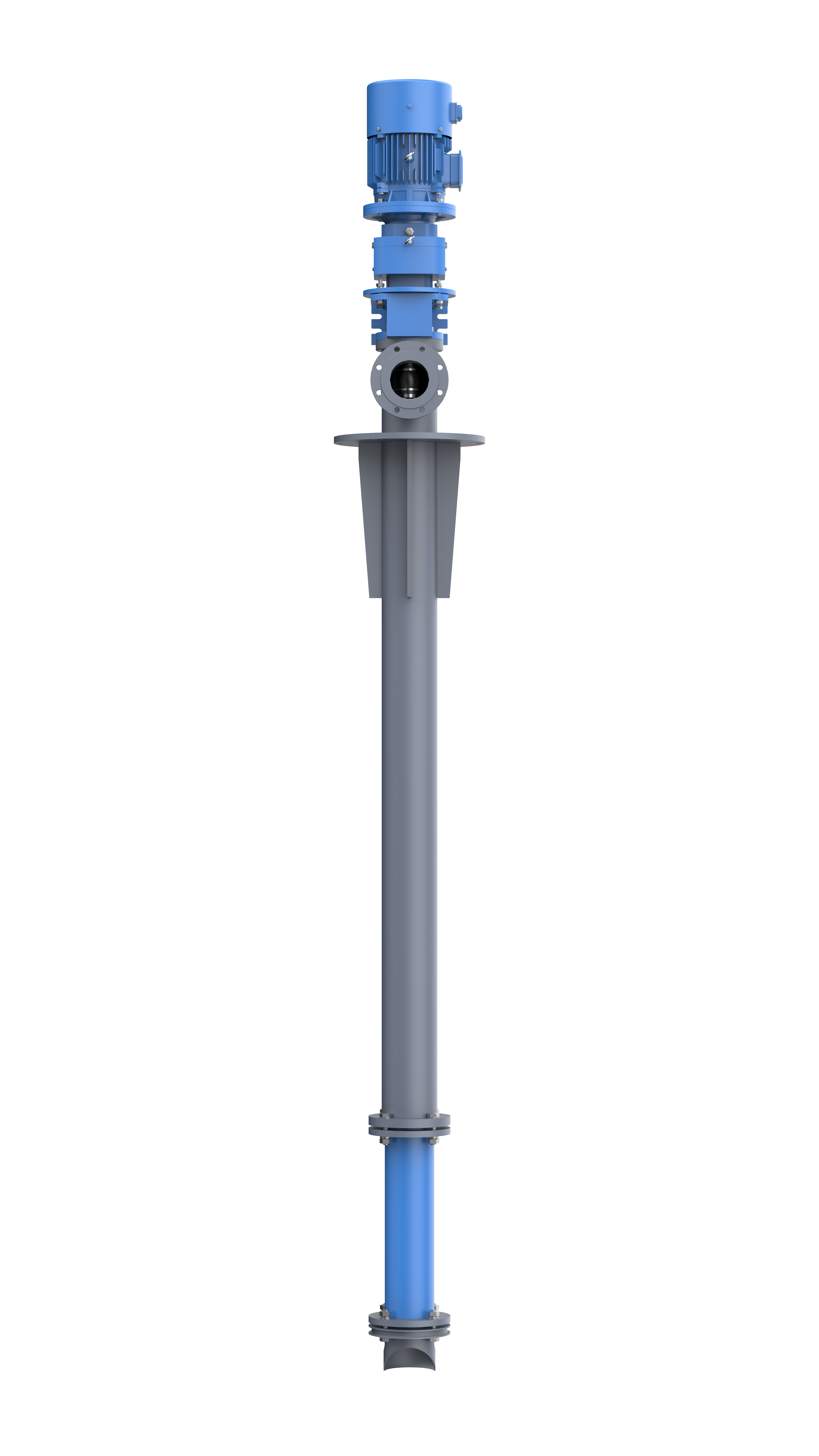

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

Pressure: 1.2MPa or higher

The viscosity of crude oil will fluctuate, and its chemical composition will also change, depending on its geological origin. Crude oil extraction involves a large number of processing steps - from cleaning to finished products.

Solution

Z.NANCHI screw pump is optimized according to various crude oil characteristics and refining processes. Some application examples are as follows:

NG series pumps transport crude oil from oil wells to oil gathering stations or between different storage facilities.

Advantages of Z.NANCHI pump design:

- The stator adopts ground to wall technology to avoid overheating

- Low pump speed, resulting in long service life

- Simple shaft sealing system

- Fully automatic control

Conclusion: Z.NANCHI pump is your preferred choice for any crude oil extraction application.

Drilling fluid and drilling mud play an important role in controlling and stabilizing drilling operations, as they are pumped into the wellbore. The returned drilling mud contains entrained rock debris; The solid must be separated before it can be returned to the mud system. The handling of this heavily contaminated drilling mud requires the use of pumps with robust engineering design.

Solution

In the application of drilling fluid handling and drilling waste management, Z.NANCHI screw pump has been successfully and reliably applied for many years.

Some application examples are as follows:

- NG series can transport water-based drilling fluids with lubrication additives without any problems

- NG series is used to feed drilling mud containing fine rock debris into the settling centrifuge

- NG series is used to clean mud pits

- NV series is used to transport drilling mud and cuttings to a vertical cuttings dryer

- NG/NP series is used to transport flocculants

Compared with other systems, Z.NANCHI single screw pump manufacturer has greatly saved costs in the application of drilling fluid handling and drilling waste management, thus enhancing their competitive advantages.

Different from oil wells, CBM wells mainly rely on drainage and pressure reduction. During the production process, there are many impurities in the coal seam water, which are corrosive and have a high gas-liquid ratio, and the water production in the previous and subsequent periods varies greatly. According to this working situation, the special Screw pump for CBM was designed based on the continuous experimental demonstration and optimization improvement of the conventional Screw pump. Because it operates at a uniform speed, there is no inertia loss of machinery and fluid flow, It can be applied not only to the production of general coalbed methane wells, but also to the production of coalbed methane wells with high gas content and high powder coal content (fly ash content ≤ 30%), ensuring the continuous and stable discharge of coalbed methane wells. At the same time, coalbed methane Screw pump has a series of advantages such as high efficiency, low energy consumption, simple structure, low price, small size, easy operation, etc.

In multiphase extraction, solids, liquids, and gases are transported from the well site to the treatment station through a single pipeline without separation.

Solution

Z.NANCHI single screw pump used for multiphase pumping and Z.NANCHI delivery has a gas yield of up to 99% when handling liquid, and the technical accessories are minimized. The rotating parts, rotor, stator, and materials in Z.NANCHI pump can adapt to every application. This can prevent the stator from overheating, and the pump can operate faultlessly at the optimal speed corresponding to the gas volume fraction.

Z.NANCHI screw pump manufacturer provide various advantages for multiphase pumping:

- High gas/liquid ratio of the pump

- Handling high sandy soil

- Conveying highly viscous fluids

- Easy handling of gas slugs

- Compact design Low operating speed

- Low investment cost

- Low operating and maintenance costs

- Fully automatic control system

- Series and parallel operation

Z.NANCHI multiphase pump can handle pressure differentials of up to 20 bar (300 PSI) and flow rates of up to 100000 barrels per day. They provide profitable and efficient alternative solutions for separation systems.