Pressure: 4.8MPa or higher

-

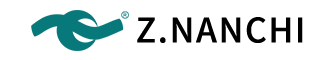

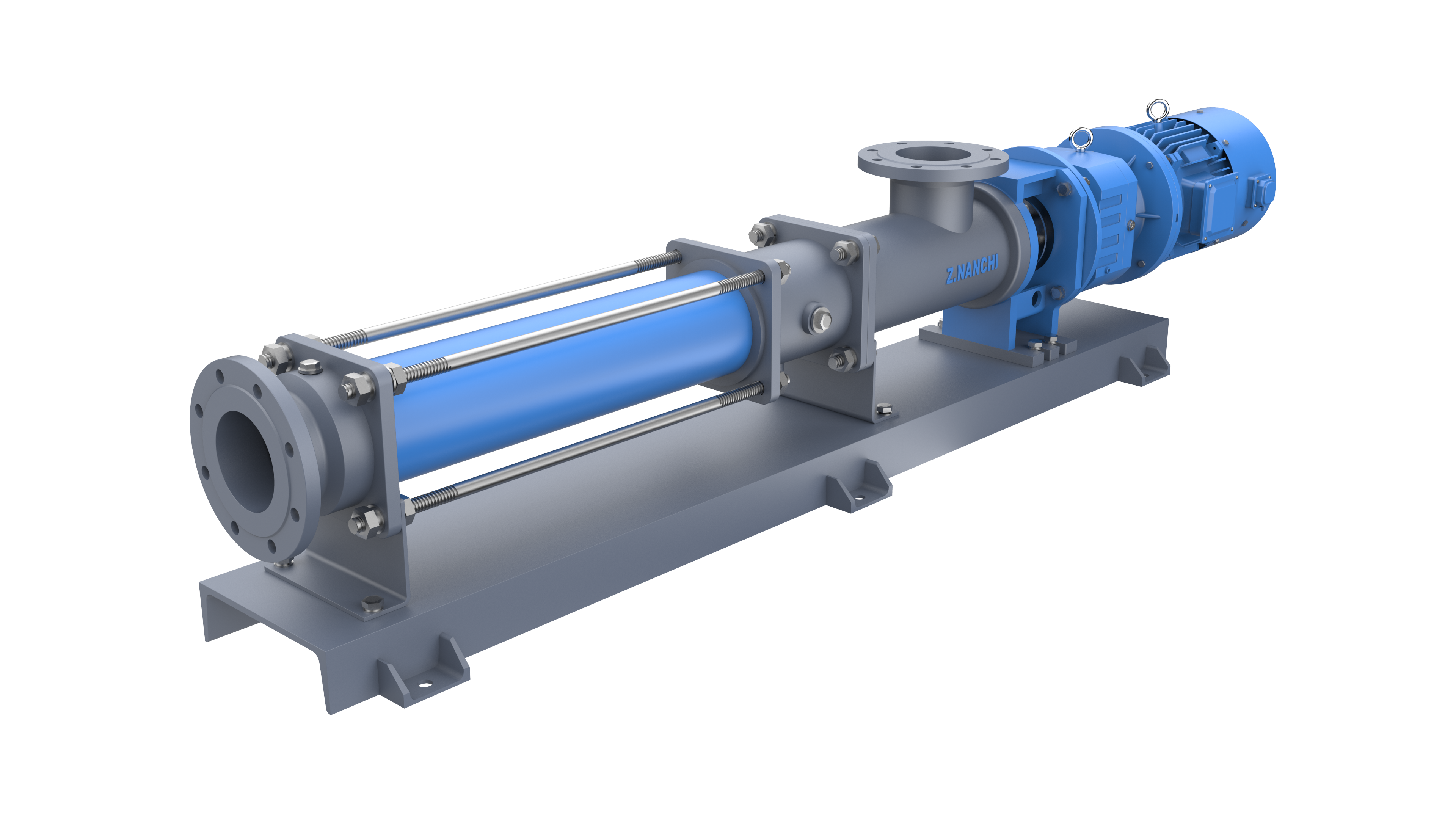

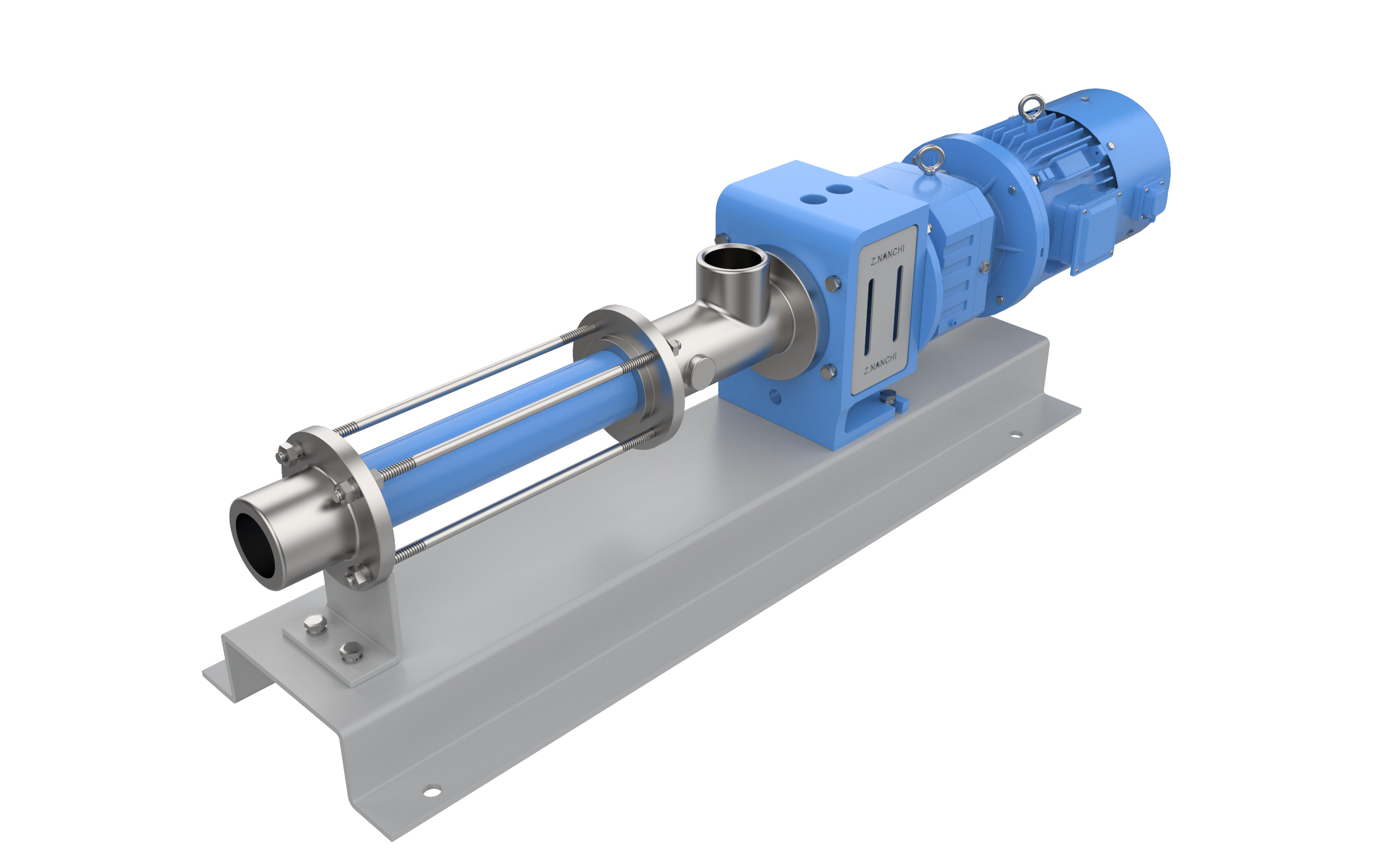

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

Pressure: 4.8MPa or higher

-

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

Pressure: 4.8MPa or higher

-

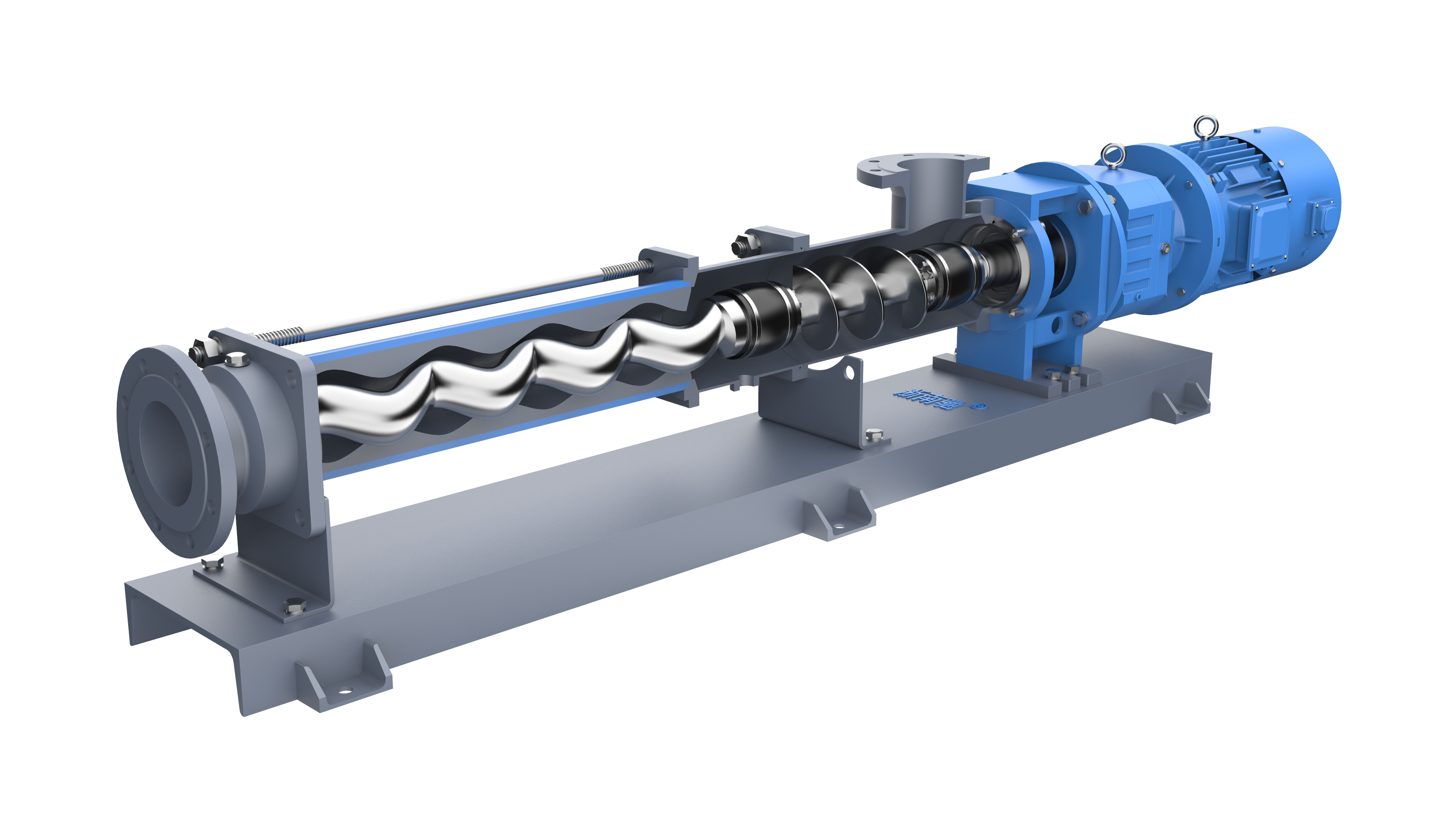

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

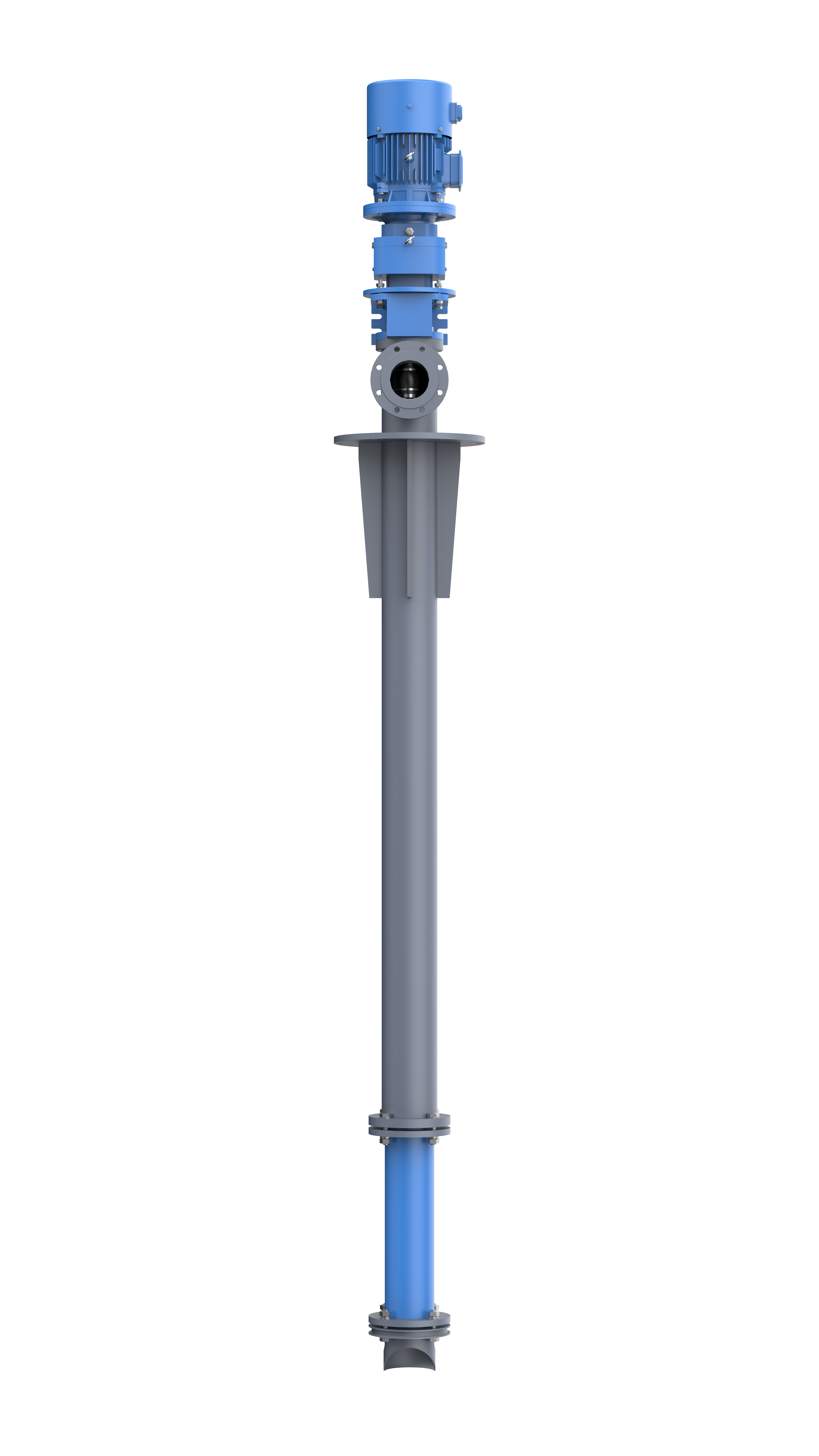

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

Pressure: 1.2MPa or higher

Due to the variable viscosity and properties of dairy products, from liquid milk and cream to solid butter and cheese. When transporting such media, it is necessary to be gentle and low in shear force to maintain the quality of the dairy product; For example, in fruit yogurt, the delivery of mixed whole fruit yogurt must be gentle to prevent damage to the quality of the fruit and dairy products. Due to the susceptibility of microorganisms in dairy products, the transportation conditions must meet high standards of hygiene.

Solution

The professional advantages of Z.NANCHI health level vertical screw pump for conveying dairy products:

- Low shear force, whether it is high viscosity or low viscosity materials

- Non destructive conveying of flexible solid materials

- Low pulsation, high linear accuracy, and stable feed pressure

- US 3-A Sanitary Standard

- Compliant with FDA and EHEDG specifications

- CIP (online cleaning) and SIP (online sterilization) design

Hopper pump designed for non flowing materials such as cheese and butter

For the added ingredients of yogurt and ice cream, Z.NANCHI pump can accurately measure the main ingredients and added ingredients simultaneously, achieving online mixing.

For the dairy industry, it is the mission of Z.NANCHI single screw pump manufacturers to ensure high hygiene standards and high product quality.

The fiercely competitive market, the increasing diversification of beverages, and strict regulations mean continuous improvement in efficiency and hygiene standards for the brewing industry and breweries.

The production of beer and alcoholic beverages is achieved through the fermentation and distillation of grains and fruits. There are many raw materials in the production process that are difficult to transport. Some of these materials are abrasive, some are very viscous, and some materials (such as yeast) require low shear force for transportation. Adopting professional whole pump transportation technology not only improves the quality of finished products and optimizes production processes, but also enables more hygienic and energy-saving treatment of production waste. Recycling production waste for energy generation is becoming increasingly important.

Solution

Application of Z.NANCHI vertical screw pump transportation technology in brewing and distillation process:

- Specially designed open hopper pumps are used in front of a sanitary sealed brewing system for mixing and conveying grains and fluids

- Very viscous materials such as hops, residue, and yeast can all be transported through a whole pump

- Gently transport yeast that is sensitive to shear force before delivery

- Accurately measure the excipients and spices added to the distillate

- Grain waste, residue, and other by-products are removed from sanitary closed systems, saving energy consumption compared to air blowing.

In short: the innovative, problem-solving whole pump delivery scheme not only saves energy, improves output, but also has high cost performance – Z.NANCHI single screw pump manufacturer in the beverage industry.

Beets and sugarcane are processed into sugar after a long process. Before concentration and crystallization, water is used to extract sugars from plant cells in order to prevent chemical damage. More than 80% of the raw sugar produced is used in other industries to produce candy, beverages, and baked goods. Less than 20% are further processed into a series of daily sugar.

Solution

In the global sugar industry, Z.NANCHI NG series standard screw pump is widely used in various fields, especially in the transportation of large-scale raw materials and additives.

The specific application precesses include:

- Waste water treatment crystallization

- Juice extraction

- Juice purification

- Fruit juice concentration

Z.NANCHI series single screw pump, due to its unique performance characteristics, has performed well in the application of sugar industry:

- Low pulse, gentle conveying

- High measurement accuracy

- High operational security

- Excellent and convenient maintenance

The transportation of the fruit and vegetable processing industry must adopt professional whole pump transportation technology that meets the process requirements, in order to achieve:

Gently transport fruit and vegetable materials to maximize the protection of nutrients in fruits and vegetables

To meet the process requirements, process the transported materials into specific sizes

Clean and economical disposal of waste generated during fruit and vegetable processing

Solution

Z.NANCHI has developed a patented concept of conveying and crushing fruits and vegetables. Apples, strawberries, carrots, onions, and many other things are hygienic chopped and pumped in a closed system while minimizing exposure to oxygen.

Z.NANCHI Sanitary Pump carefully pumps fruit pulp and juice for further processing

Preparing ready to eat products from fruits and vegetables generates a large amount of organic waste. Z.NANCHI technology can directly remove these wastes from the closed system from the processing area.

Capable of handling all types of waste:

- Including stone fruits

- Remove sanitary waste from high-end care areas

- Energy and labor savings compared to alternative systems

- Waste volume can be reduced by up to two-thirds

- Save disposal costs

- Hygienic, gentle and effective, from inhalation to waste removal

Z.NANCHI single screw pump is very suitable for handling fruits and vegetables.

To ensure the provision of safe meat products to consumers, the processing and transportation of livestock and poultry meat products are strictly regulated by various laws and health regulations. The disposal of organic waste from meat products must also comply with strict rules and regulations.

The disposal methods for the large amount of processing waste and by-products generated during the processing of these meat products are also subject to relevant disposal regulations.

Solution

We use Z.NANCHI food hygiene grade pump for the food industry to transport meat products and minced meat. Its professional and gentle delivery ensures the quality and integrity of the product. If it is necessary to transport large pieces of material, including complete chicken breasts, we can ensure that they are not damaged by adopting special designs.

Our pump is designed for CIP (online cleaning) and SIP (online sterilization).

Meets the requirements of the US 3-A health level standard.

Z.NANCHI single screw pump is an ideal choice to send by-products including blood, viscera, skin, head or other parts out of the production area.

The NH type pump with integrated cutting function completes the cutting of materials simultaneously during the conveying process. Even whole meat poultry, such as dead chickens or substandard chickens, can be treated with this pump type. By sealing the pipeline and using a pump to remove potential pollutants, ensure that hygiene standards are met.

Z.NANCHI crushing and cutting machine can cut various waste materials into extremely fine pieces, even solid materials such as small bones or cartilage become a part of the entire pump transportation process.

Using the Z.NANCHI method to handle meat processing by-products and waste to ensure:

- Biosafety and compliance with relevant waste disposal regulations

- Waste reduction

- More energy-efficient system

- Reduce labor costs

In 2013, the per capita sugar intake exceeded 32 kg, and this figure is still steadily increasing. Z.NANCHI single screw pump is widely used in candy factories all over the world. From cocoa, chocolate, caramel, soft candy, jelly to hard candy, etc., all these sweets must be handled with special care in high sanitary workshops.

Solution

Due to its many design advantages, Z.NANCHI screw pump solution is particularly suitable for the candy industry:

- Soft, low pulsation pumping of shear sensitive and viscous media

- High metrological accuracy independent of viscosity changes

- Able to handle soft solids without damage

- 3-A Health Standard Certification in the United States

- CIP and SIP design

- Double layer jacket design for constant temperature during operation, such as for chocolate

- Open hopper design for products with extremely high viscosity.

Typical products and components processed include:

Gel jelly

caramel

licorice, seasonings, pigments

chocolate, creamy gummy, nougat,

cream

Accurate measurement and gentle conveying are the professional advantages of Z.NANCHI Food Hygiene Grade Pump in the sugar industry.